What is the working principle of FPC glue dispensing machine

source:www.8866mir.com | Release time:2025年01月14日The FPC glue dispenser first needs a stable glue supply system. Usually, the glue solution is stored in a rubber drum or hose. The adhesive liquid is transported to the adhesive supply area near the dispensing needle under its own gravity or air pressure. For example, for some adhesives with low viscosity, slow flow can be achieved by relying on gravity; For adhesives with high viscosity, it is necessary to apply a certain pressure to the glue barrel through a pneumatic device (such as a pneumatic pump) to send the glue to the dispensing position.

2. Glue dispensing control principle

Time pressure control method: This is a common control method. There is a pressure control system inside the glue dispensing machine, which controls the flow rate of the glue by adjusting the air pressure inside the glue supply pipeline. At the same time, combined with time control, the amount of glue is determined by controlling the length of time the glue liquid flows out. For example, when a small glue point needs to be clicked, a lower air pressure and shorter glue dispensing time will be set; For longer glue lines, the glue dispensing time will be appropriately extended. Specifically, the system will open the dispensing valve according to preset parameters, and the adhesive liquid will flow out of the needle under the pressure of air. After a correctly calculated time, the valve will close and stop dispensing.

Piston control method: This method is similar to the principle of a syringe. There is a piston structure in the dispensing machine, and when the piston moves upward, the adhesive liquid is sucked into the piston chamber; When the piston moves downwards, the glue is squeezed out through the needle. The movement of the piston can be driven by an electric motor or air pressure. By correctly controlling the stroke and speed of the piston, the amount of glue can be controlled correctly. For example, for some high-precision FPC packages, piston control can more accurately squeeze out trace amounts of glue, avoiding excessive or insufficient glue.

Screw control method: The glue liquid is transported and extruded in the pipeline through the rotation of the screw. When the screw rotates, it will generate a forward thrust on the glue, causing the glue to flow along the direction of the screw thread and be squeezed out from the needle. The speed of the screw can be controlled correctly, and the faster the speed, the greater the flow rate of the adhesive. This method is suitable for adhesives with high viscosity and poor fluidity, as the rotation of the screw can effectively overcome the resistance of the adhesive and achieve stable dispensing.

3. Principle of motion control

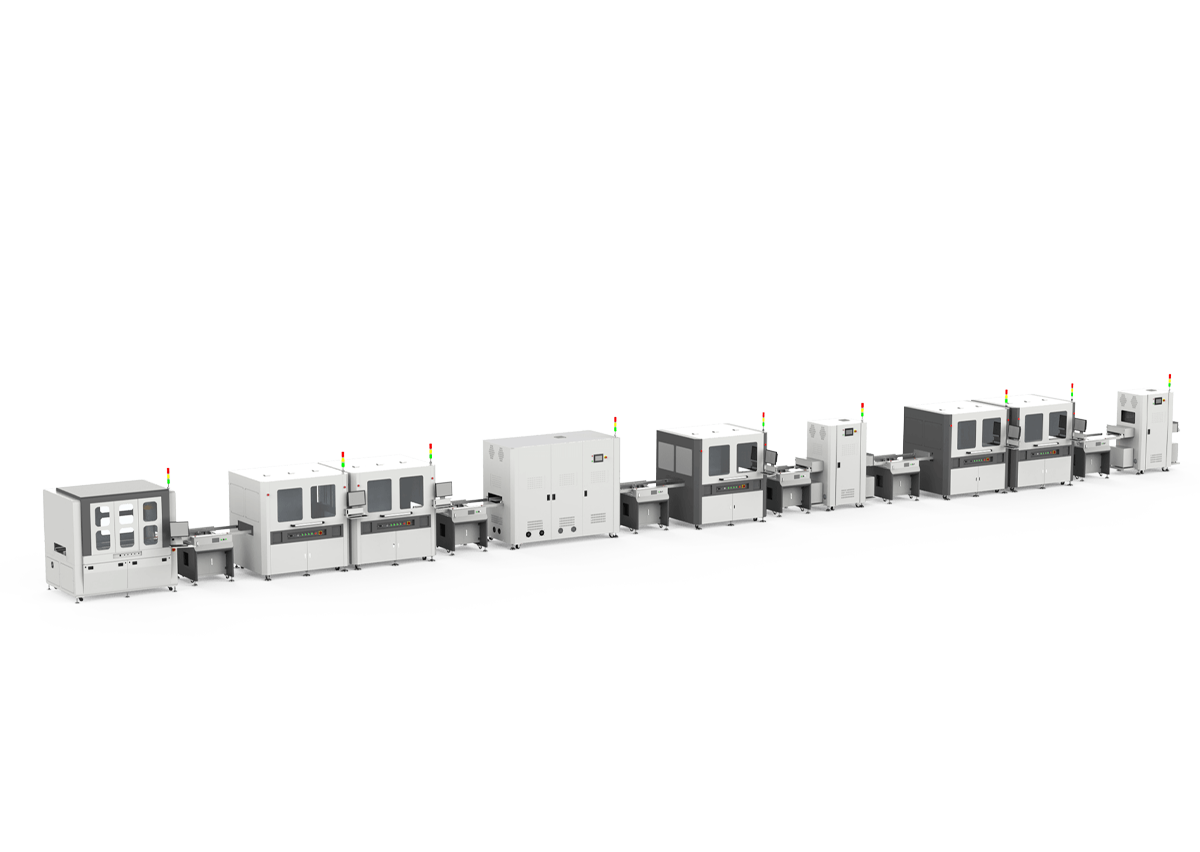

FPC glue dispensing machines are generally equipped with high-precision motion control systems, which are usually composed of motors, screws, guide rails, and motion control cards. The motor drives the screw to rotate, and the screw drives the dispensing needle to perform correct linear motion (X, Y axis direction) on the guide rail. For example, when dispensing on FPC circuit boards, the control system will correctly move the dispensing needle to each position that needs to be dispensed according to the pre programmed path. Some dispensing machines also have Z-axis motion control to adjust the distance between the needle and the FPC board, ensuring the correct dispensing height and preventing the needle from damaging the circuit board or dispensing incorrectly due to excessive distance.

4. Visual positioning principle (if there is a visual system)

Some good FPC dispensing machines are equipped with visual positioning systems. Its working principle is to capture images of the FPC circuit board through a camera, and then analyze the images using image recognition software. The software will recognize specific marks on the circuit board (such as positioning holes, circuit patterns, etc.) and calculate the position coordinates of these marks. Compare and calibrate these coordinates with the pre-set dispensing position coordinates to achieve high-precision dispensing position positioning. For example, in some high-precision FPC chip packaging and dispensing processes, the visual positioning system can correctly find the position of the chip pins, and the error can be controlled within a very small range to ensure that the glue is correctly applied around the pins.

中文

中文 英文

英文

WeChat official account

WeChat official account

Scan your phone once

Scan your phone once

Wechat ID:

Wechat ID:

wechat

wechat

contact

contact

phone

phone